(Battery-Filler)

(It's also good for removing bubbles if you're using zinc and nitric

acid.)

(Battery-Filler)

(It's also good for removing bubbles if you're using zinc and nitric

acid.) Test Jar, empty.

Test Jar, empty.  Test Jar, in use.

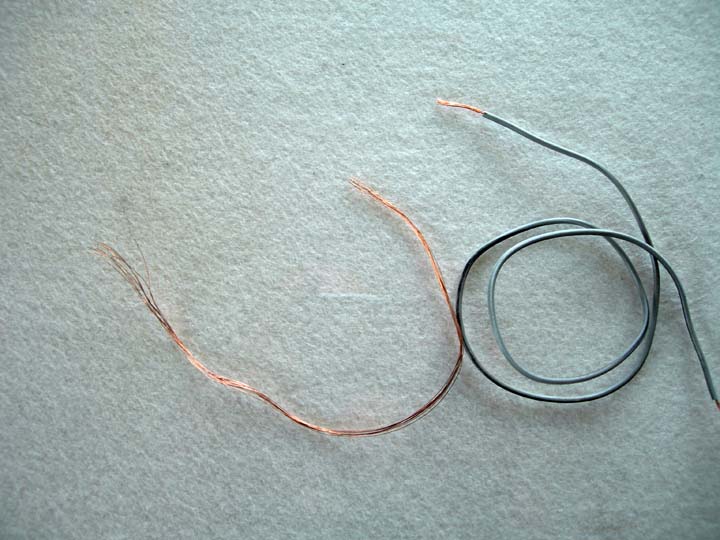

Test Jar, in use.  Thin copper wire.

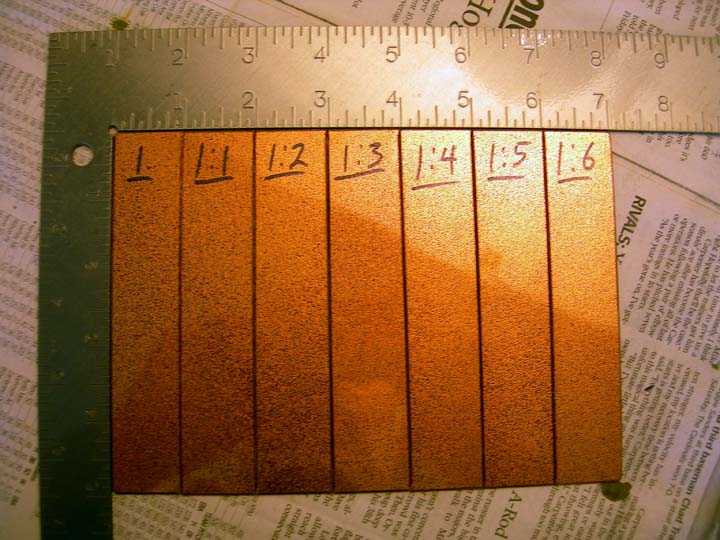

Thin copper wire. These are the 7 test plates, aquatinted.

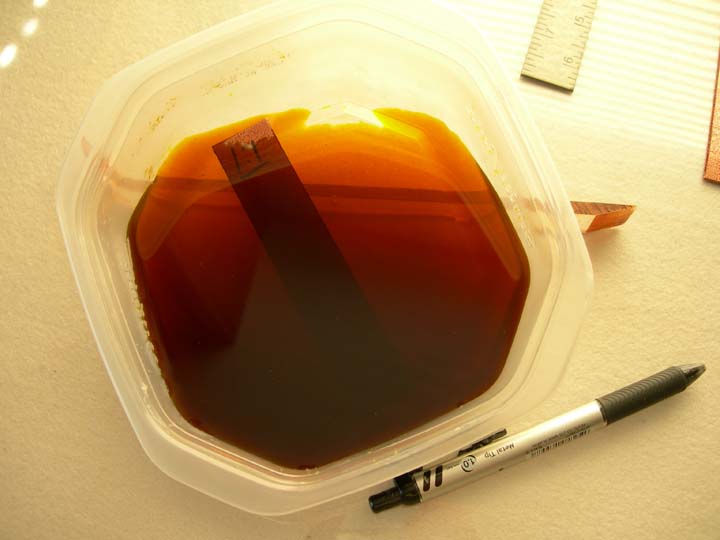

These are the 7 test plates, aquatinted. This is a test-plate in the

ferric chloride.

This is a test-plate in the

ferric chloride.| Test Solution (each plate etched for 15 minutes) |

Time required to etch through the wire |

| 1 (full strength, 40° Baume) | 2 hrs. 9 minutes |

| 1:1 (1 pint full strength, 1 pint added water) | 7 min. 44 sec. |

| 1:2 (1 pint full strength, 2 pints added water) | 8 min. 46 sec. |

| 1:3 | 10 min. 22 sec. |

| 1:4 | 13 min. 44 sec. |

| 1:5 | 16 min. 53 sec. |

| 1:6 | 18 min. 26 sec. |

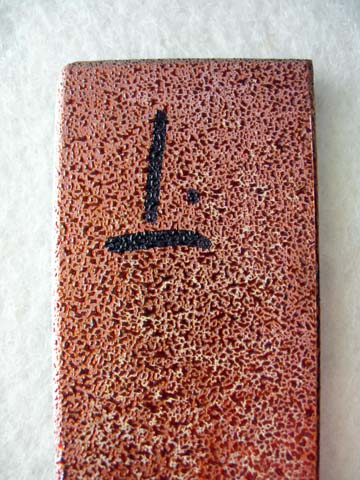

White deposits formed when etching with full strength solution.

White deposits formed when etching with full strength solution.  White deposits compared to normal etch when solution is diluted 1:1.

I didn't try etching a plate upside-down in the strong solution to

see if there were less white deposits than when etching it face-up (all

plates were etched face-up only), but I suspect that it wouldn't

make much difference in the etching action because the wire showed the

same dramatic difference in etching times between the full strength

solution and the diluted solutions as the plates did, though I never

noticed any white deposits on the wire. If it was a gravity-related

issue of something accumulating on the plate when face-up and blocking the

etchant, it seems the wire should have etched dramatically faster

than the plate in the full strength solution. I've also never

used a vertical tank (or etched a plate face-down), so if using one or

positioning a plate face-down fixes the problem then it would appear to be

gravity-related. I've always gotten clean etches using diluted ferric

chloride and a face-up plate, so I've never worried about it.

White deposits compared to normal etch when solution is diluted 1:1.

I didn't try etching a plate upside-down in the strong solution to

see if there were less white deposits than when etching it face-up (all

plates were etched face-up only), but I suspect that it wouldn't

make much difference in the etching action because the wire showed the

same dramatic difference in etching times between the full strength

solution and the diluted solutions as the plates did, though I never

noticed any white deposits on the wire. If it was a gravity-related

issue of something accumulating on the plate when face-up and blocking the

etchant, it seems the wire should have etched dramatically faster

than the plate in the full strength solution. I've also never

used a vertical tank (or etched a plate face-down), so if using one or

positioning a plate face-down fixes the problem then it would appear to be

gravity-related. I've always gotten clean etches using diluted ferric

chloride and a face-up plate, so I've never worried about it.